FDI Creative Services

APP

The Advanced Pipeline Plough has anextensive track record for the Post-Lay Burial of large diameter pipelines and flowlines in multiple soils using multi-pass ploughing. The flexible heave compensated LARS allows operation in extreme environmental conditions. The APP has also completed extensive pre-cut burial workscopes to specification in addition to the lowering of decommissioned surface laid pipelines.The innovative technology of adjustable skids enhances burial performance in a variety of soil conditions, providing a reliable trenching solution.

AMP500

The Advanced Multi-Pass Plough has an extensive track record for the Pre-Cut and Post-Lay protection of large diameter pipelines, flowlines and power cables. The AMP500 plough spread is proven in multiple seabed conditions globally and includes a heave compensated Launch and Recovery System that allows the plough to perform in extreme environmental conditions.

ACP2

The ACP2 is the first plough in the offshore industry fully designed for optimum performance in all areas, but specifically for the safe handling and burial of large diameter power cables to 3.3m.

V8 SII HD

The V8 incorporates the very latest cutting-edge hardware and software technology, and sports a pedigree that can be traced back to the legendary SeaOwl.

V8 Offshore

The V8 incorporates the very latest cutting-edge hardware and software technology, and sports a pedigree that can be traced back to the legendary SeaOwl.

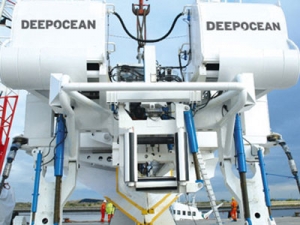

Schilling Robotics UHD 200

The UHD is a 200HP industry leading work class ROV, suitable for deployment to 4000m. The multifunctional design has a proven capability in the provision of Survey, Intervention and Construction workscopes, and supports virtually all subsea heavy work requirements. The UHD is designed for projects requiring significant power to handle, position and install subsea field equipment, with precise and stable control provided through advanced automatic piloting modes. The AHC Launch and Recovery System allows rapid, safe deployment in more challenging conditions.

Triton XL

The 100HP TRITON XL offers a comprehensive combination of thrust, payload, through-frame lift and sensor interface. It supports virtually any offshore heavy work requirement including: Drill support, Construction support, Platform cleaning and inspection, Subsea cable burial and maintenance, Deepwater salvage, Remote deployment, Subsea pipeline completion, Suction Pile installation.

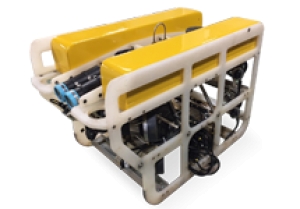

Surveyor Plus (SEAROV)

Thruster configuration, shape and light weight construction provide an ROV ideally suited for survey operations with the payload and interfaces to easily accommodate survey peripherals. This versatile ROV is also widely used for drill support, observation and inspection applications. The SURVEYOR Plus systems are also modified to deploy SEAROV SRCT innovative cleaning tool.

Supporter

The Installer / Supporter / Constructor can accommodate up to 24 additional tooling hydraulic functions, 20 additional survey sensors and 8 cameras. All hydraulic functions are proportionally controlled, and there is ground fault monitoring on all channels in the electronics system. The ROV control system offers a variety of auto-functions like AutoPOS and AutoTRACK capabilities.

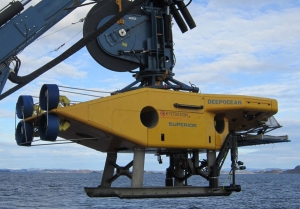

Superior Survey ROV

Building on DeepOceans extensive experience in seabed mapping and ROV pipeline inspection, the SUPERIOR ROV provides a new level of ROV survey performance. Its hydrodynamic shape, power and modular design provides unmatchable operational flexibility and data quality. The ROV is equipped with the latest technology in navigation- and sensor systems. Its seamless integration with the ROV control system ensures very stable and precise ROV flying capabilities.